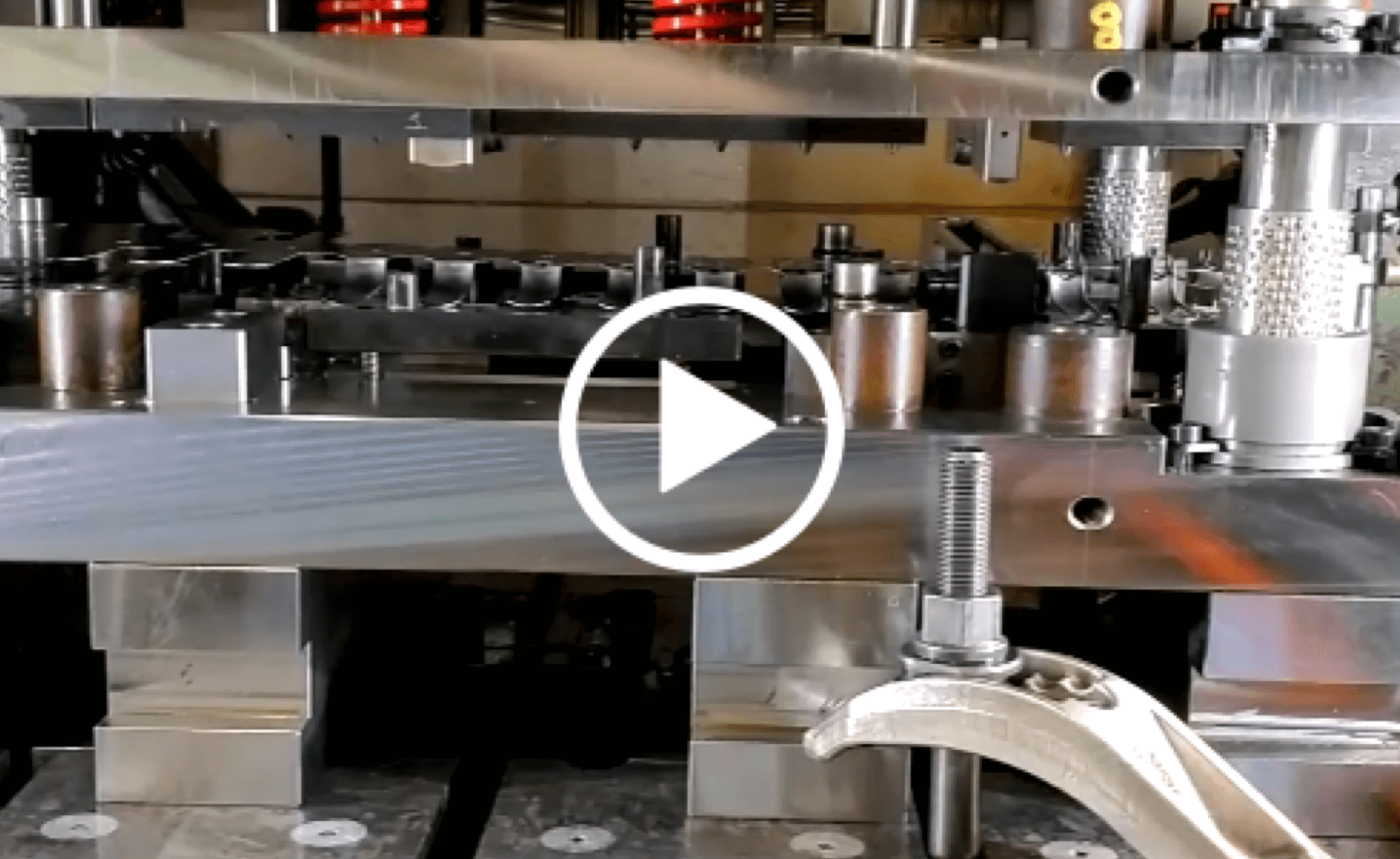

Our know-how in cutting and stamping

Our company has extensive expertise in cutting and stamping metal parts. We manufacture parts and sub-assemblies according to your specifications, from prototype to mass production.

The cutting and stamping of technical industrial parts is the main activity of Joubert Lacour.

Our experience allows us to meet your needs and work with all types of metal, from aluminium to stainless steel, brass, bronze and copper in thicknesses ranging from 0.5 mm to 5 mm.

The capacity of our facilities allows us to produce high quality technical parts in small and large series. We meet the needs of our customers with requirements ranging from 500 parts per year to 1,000,000 parts per year.

To carry out our series production, we have a complete and efficient machine park.

Our machine park consists of automatic presses, but also of rework presses:

- 8 automatic press lines from 80 to 250 t

- 15 rework presses from 30 to 150 t

- A tribofinishing and degreasing workshop

- A workshop for the assembly of parts by riveting/undergluing

We are able to supply complex parts thanks to our strong network of subcontractors and local suppliers who offer different types of finishes and services:

- Tribofinishing

- Heat treatment

- Anodising

- Cataphoresis

- Zinc plating

- Nickel plating…

What is the cutting process?

This process consists of cutting a sheet of metal using specific tools to create predefined shapes. The product obtained by this process is then used to perform a stamping operation.

What is the stamping process?

The stamping process is used to cold form metal parts by applying force to a sheet of metal. This force is applied using a specially designed punch and die.

ADVANTAGES OF STAMPING:

- Cost: Stamping is a very efficient and economical production process for high volume parts. It can be automated to increase productivity and reduce labour costs.

- Speed: Modern stamping machines can produce parts quickly and consistently. This allows for quick response to customer requests and reduced delivery times.

- Accuracy: Stamping can produce parts with a high degree of accuracy, which is important for applications that require tight tolerances.

- Flexibility: Stamping can be used to produce a wide variety of parts, from simple to complex, using a wide variety of materials.

- Durability: Stamped parts can be very strong and durable, as the manufacturing process strengthens the material and increases its resistance.

- Design: Stamping allows the production of parts with complex shapes and patterns, which offers great flexibility in terms of design.

- Material savings: Stamping allows efficient use of raw material, minimising waste and reducing costs.

Full support for all your cutting/stamping projects

From the design of the tools to the technical stamping of your metal parts, Joubert Lacour provides complete support by placing all its know-how and experience at your disposal. Consult us for all your cutting and stamping projects.